Tantalum – An Indispensable Metal for High-Tech Applications

What is Tantalum and Why It is Indispensable

Tantalum is a rare and fascinating metal that plays a key role in many industries due to its special properties. It is a gray-blue, extremely corrosion-resistant element with the chemical symbol "Ta," which also belongs to the group of transition metals. Tantalum is frequently used in the electronics industry, especially for capacitors and high-temperature applications. Its excellent heat resistance and electrical conductivity make it a sought-after material in medical technology, aviation, and the manufacture of special alloys.

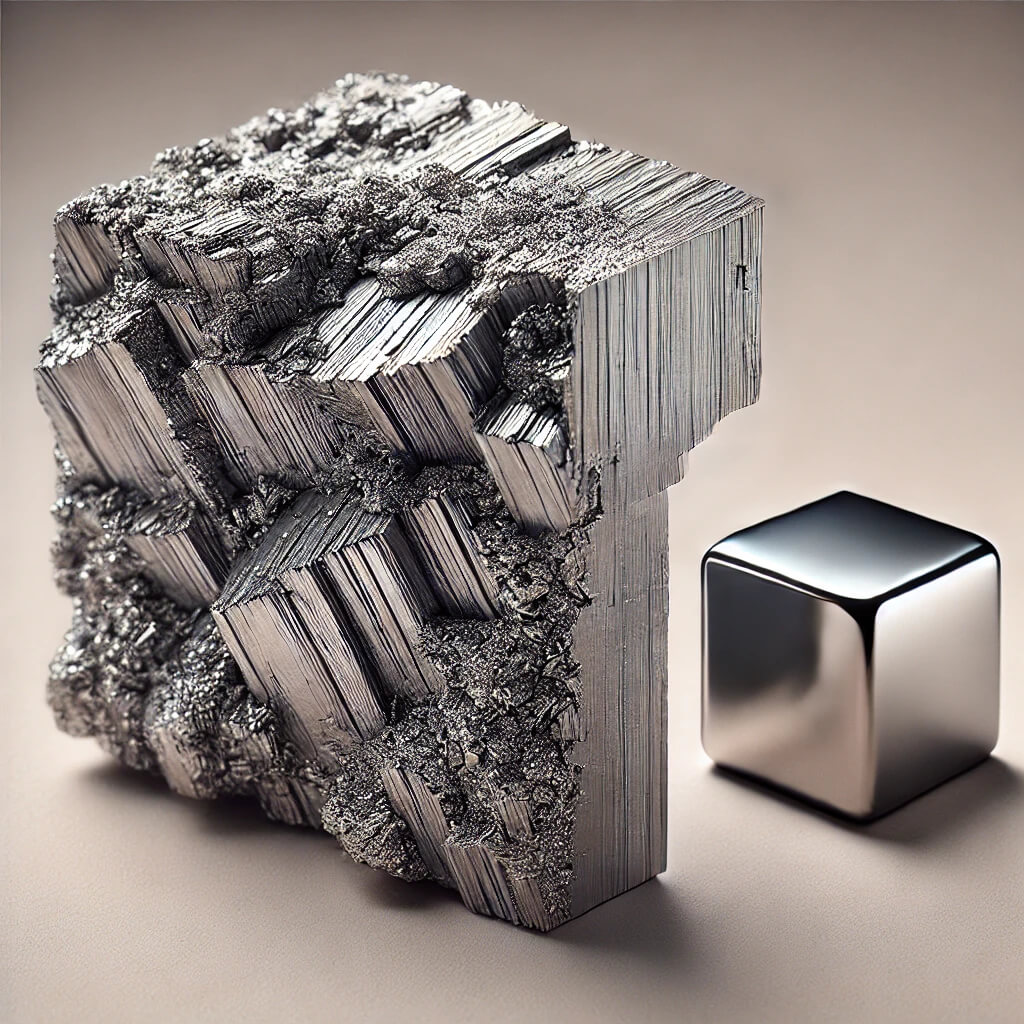

Chemical and Physical Properties of Tantalum

Tantalum is characterized by an exceptionally high melting temperature of about 3,020 degrees Celsius and superior corrosion resistance, even against most acids. These properties make it ideal for use in aggressive chemical environments and at extreme temperatures. Moreover, tantalum is extremely malleable, which makes it particularly suitable for processing into thin wires and foils.

Occurrence and Extraction of Tantalum – Your Path to Purchase

Tantalum is primarily extracted from minerals such as coltan (a mixture of columbite and tantalite), which is mainly mined in countries like the Democratic Republic of Congo, Brazil, and Australia. The extraction of tantalum involves complex extraction and refining processes, as it often occurs together with niobium in the same ores. The purchase of tantalum products is done through specialized dealers who offer it in forms such as powder, wires, rods, or sheets.

How Tantalum is Mined and What That Means for the Price

The extraction of tantalum is laborious and often associated with ethical challenges, particularly regarding the conflict minerals issue in Africa. After mining, the material is refined through chemical and physical processes to obtain pure tantalum. This complex process directly affects the pricing of various tantalum products available on the market.

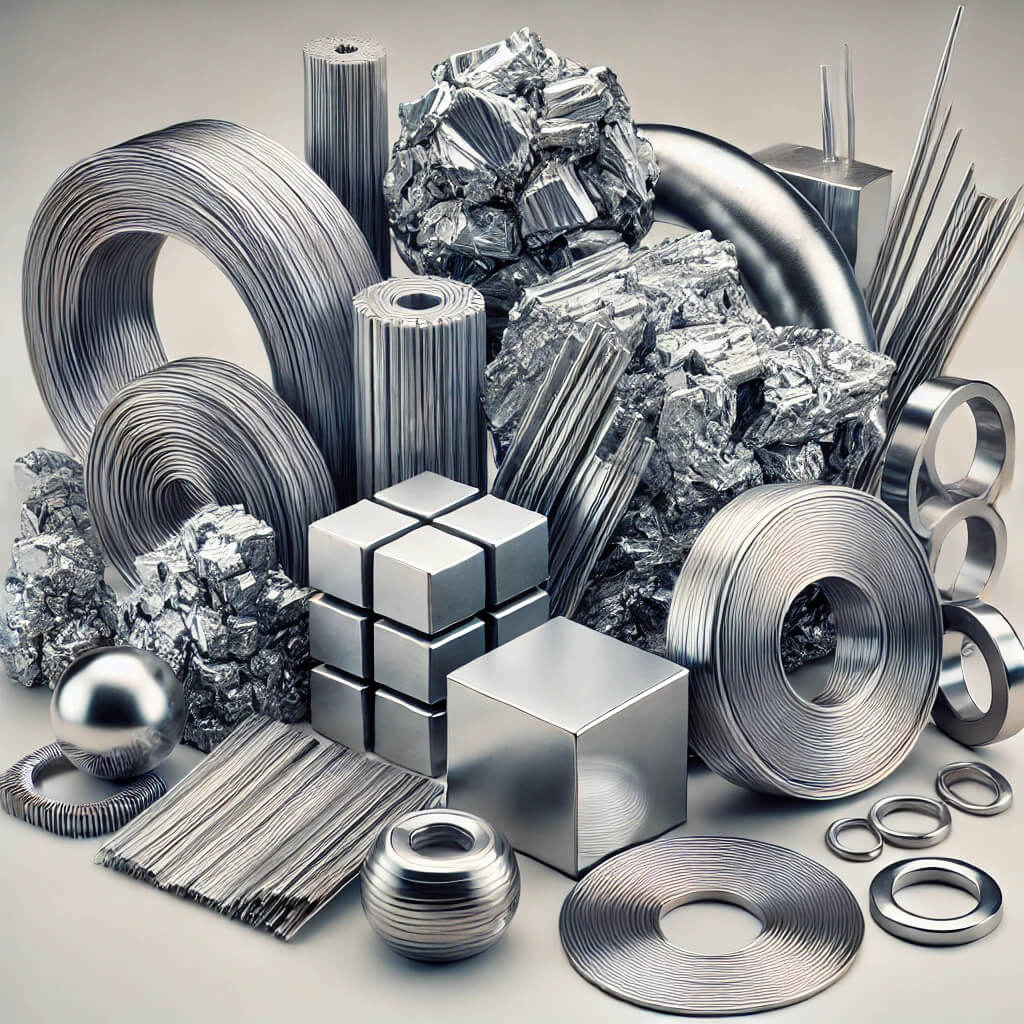

Buying Tantalum – Your Options at a Glance

Tantalum Sheets and Foils – Precision for High Technology

Tantalum sheets and foils are known for their extreme corrosion resistance and stability at high temperatures. They are used in the electronics industry and in chemical processes where reliability and longevity are essential. You can purchase high-quality tantalum foils and sheets in various dimensions and thicknesses from specialized providers.

Tantalum Rods and Tubes – Durability and Resistance

Rods and tubes made of tantalum are extremely resistant to chemical influences and mechanical stresses. They are frequently used in aviation, medical technology, and the chemical industry, where the highest demands are placed on material stability.

Tantalum Wires – Flexibility and Conductivity

Tantalum wires are extremely flexible and have high electrical conductivity, making them an indispensable material for capacitors, semiconductors, and special electronic components. These wires are also used in medical technology for implants, as tantalum is biocompatible and does not cause reactions in the body.

Tantalum Screws and Fasteners – Highest Reliability

Fastening elements such as screws and nuts made of tantalum are particularly corrosion-resistant and are excellent for extremely aggressive chemical environments. These products are primarily used in the chemical industry and in medical applications, where durability and safety are crucial.

Advantages of Tantalum in Technical Applications

Heat Resistance and Corrosion Resistance – Tantalum in Extreme Environments

Tantalum, with its high melting point and exceptional corrosion resistance, is particularly suitable for applications that are exposed to extreme conditions. This makes it an ideal material for use in the chemical industry, in the manufacture of heat exchangers, and in aerospace technology.

Biocompatibility – Tantalum in Medical Technology

One of the outstanding properties of tantalum is its biocompatibility. It does not react with tissue or body fluids, making it ideal for use in medical implants and surgical devices. Tantalum is frequently used in hip joint prostheses, surgical staples, and stents.

Sustainability in Purchasing Tantalum

Recycling of Tantalum – Contributing to Resource Conservation

Tantalum is largely recyclable, particularly in the electronics industry where old tantalum capacitors and components can be reused. This helps reduce the need for primary tantalum mining and supports sustainable production processes.

Future Perspectives for Tantalum – Focus on Innovations

Tantalum will continue to play a crucial role in the development of new technologies in the future. Especially in the electronics and energy sectors, it will contribute to efficiency improvements in conjunction with new alloys and materials. The demand for tantalum is expected to rise due to the growing need for high-performance electronic components and sustainable materials.

Conclusion: Tantalum – The Key Metal for Advanced Technologies

Tantalum is an indispensable material for demanding applications in electronics, medical technology, and aerospace. Its unique properties, such as extreme heat resistance, corrosion resistance, and biocompatibility, make it a key factor in modern technology development. Thanks to its recyclability, tantalum also contributes to sustainability in the industry and will continue to play a central role in the innovation of high-performance technologies in the future.

FAQs about Tantalum

- What makes tantalum so special? Tantalum is characterized by its extremely high corrosion resistance, heat resistance, and biocompatibility, making it indispensable for many high-tech and medical applications.

- Where can I buy tantalum products? Tantalum products such as wires, sheets, rods, and foils can be purchased from specialized metal dealers.

- What products are made from tantalum? There is a variety of products, including foils, sheets, wires, rods, tubes, and medical implants.

- How is tantalum used? Tantalum is used in electronics, medical technology, aerospace, and the chemical industry.